“Mechanical Engineers – World Revolves Around Us”

The Department of Mechanical Engineering at MPSTME, Mumbai established in the year 2010, comprises 17 full-time faculty members and 7 full-time administrative and technical support staff. The department offers programmes in B Tech, MBA Tech, and B Tech (Integrated). The department has a number of laboratories, equipped with some state-of-the-art scientific instruments and systems. Along with ensuring a sound base in fundamentals, over the years it has been the department’s endeavor to keep abreast with the latest advancements in the field. In this vein, the department has cultivated into areas of Composites, Robotics, Aerospace, Nanotechnology, and Additive Manufacturing. The research work of the faculty members is spread over a vast range of domains, which, can be categorized broadly into three streams: Thermal and Fluids Engineering, Design Engineering, and Manufacturing Engineering.

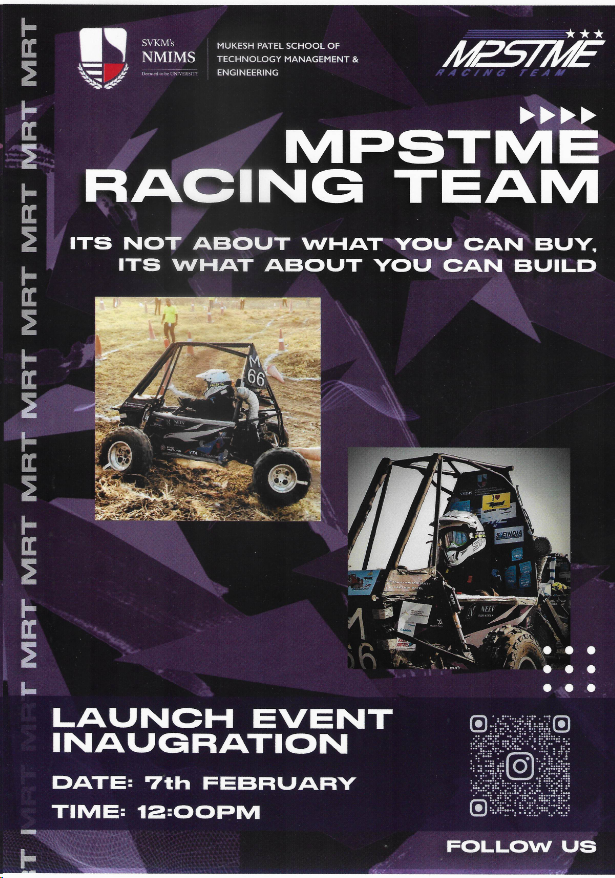

Professional Societies & Student Clubs: Student Communities, Committees, or Clubs

To be a center of excellence in Mechanical Engineering for education and research to create competent Mechanical Engineering graduates who can be employable in the industries and be part of innovation, research, problem-solving, and entrepreneurship to help mankind in particular and society in general.

PO1: Engineering Knowledge: Apply knowledge of mathematics, natural science, computing, engineering fundamentals and an engineering specialization as specified in WK1 to WK4 respectively to develop to the solution of complex engineering problems.

PO2: Problem Analysis: Identify, formulate, review research literature and analyze complex engineering problems reaching substantiated conclusions with consideration for sustainable development. (WK1 to WK4)

PO3: Design/Development of Solutions: Design creative solutions for complex engineering problems and design/develop systems/components/processes to meet identified needs with consideration for the public health and safety, whole-life cost, net zero carbon, culture, society and environment as required. (WK5)

PO4: Conduct Investigations of Complex Problems: Conduct investigations of complex engineering problems using research-based knowledge including design of experiments, modelling, analysis & interpretation of data to provide valid conclusions. (WK8).

PO5: Engineering Tool Usage: Create, select and apply appropriate techniques, resources and modern engineering & IT tools, including prediction and modelling recognizing their limitations to solve complex engineering problems. (WK2 and WK6)

PO6: The Engineer and The World: Analyze and evaluate societal and environmental aspects while solving complex engineering problems for its impact on sustainability with reference to economy, health, safety, legal framework, culture and environment. (WK1, WK5, and WK7).

PO7: Ethics: Apply ethical principles and commit to professional ethics, human values, diversity and inclusion; adhere to national & international laws. (WK9)

PO8: Individual and Collaborative Team work: Function effectively as an individual, and as a member or leader in diverse/multi-disciplinary teams.

PO9: Communication: Communicate effectively and inclusively within the engineering community and society at large, such as being able to comprehend and write effective reports and design documentation, make effective presentations considering cultural, language, and learning difference.

PO10: Project Management and Finance: Apply knowledge and understanding of engineering management principles and economic decision-making and apply these to one’s own work, as a member and leader in a team, and to manage projects and in multidisciplinary environments.

PO11: Life-Long Learning: Recognize the need for, and have the preparation and ability for i) independent and life-long learning ii) adaptability to new and emerging technologies.

The department offers programmes in BTech, MBA Tech, and BTech (Integrated).

The department comprises 20 full-time faculty members and 9 full-time administrative and technical support staff.

The Mechanical Department at MPSTME is indulged in research in the areas of design, manufacturing, and thermal engineering including the latest areas like renewable energy, supply chain, composite materials, additive manufacturing, and automation. Some of the prominent research work of the department are given below:

AY 2023-24

| Solar Tracking Systems – A Review | Abhishek Priyam | 2023-24 | Journal of Mines, Metals & Fuels, |

| A Review on “Wind energy fuel as a Power Source for Automobiles” | Abhishek Priyam | 2023-24 | Journal of Mines, Metals & Fuels, |

| Assessing Key Success Elements for the Economic Sustainability of the Robotics Industry | Girish Bagle, SawanKumar Naik | 2023-24 | European Economic Letters |

| Investigation on Mechanical Properties of AA6061/TiB2 Metal Matrix Composites Fabricated by Squeeze Casting Process | Samadhan Deshmukh, Dr. Asha Ingle and Dr. Dineshsingh Thakur | 2023-24 | NanoWorld Journal |

| Assessing Key Success Elements for the Economic Sustainability of the Robotics Industry | SawanKumar Naik, Girish Bagle | 2023-24 | European Economic Letters |

| A Review of Solar Still Technology: Solution for Water Scarcity | Aniket Chorghe, Ameya Dhavale, Vedant Mehta, Prahnesh Rao, Neepa Patel ,Abhishek Priyam | 2023-24 | International Journal of Environmental science and Technlogy |

AY 2022-23

| A thorough review of the existing concentrated solar power technologies and various performance enhancing techniques | Abhishek Priyam, Nakul Kurkute | 2022-23 | Journal of Thermal analysis and Calorimetry |

| An encapsulation on Nano Drug Delivery Systems and their Probable Applications | Likhit Sawant, Jayvardhan Vyas, Parvez Surani, Jatin Dalmia, Aliasgher Tinwala and Samadhan Deshmukh* | 2022-23 | NanoWorld Journal |

| Optimization of stir casting process parameters in the fabrication of aluminium based metal matrix composites | Samadhan Deshmukh, Dr. Asha Ingle and Dr. Dineshsingh Thakur | 2022-23 | Material Today: Proceedings (In press) |

| Experimental investigation on mechanical properties of TiB2 reinforced AA6061 metal matrix composites fabricated by stir casting process | Samadhan Deshmukh, Dr. Asha Ingle and Dr. Dineshsingh Thakur | 2022-23 | Material Today: Proceedings (In press) |

From 2019 to 2022

| Parametric review of microwave-based materials processing and its applications | Dr. Asha Ingle | 2019-20 | Journal of Materials Research and Technology |

| Effect of notch-depth ratio on intermittent electromagnetic radiation from Cu-Ni alloyunder tension | Ranjana Singh | 2019-20 | Materials Testing |

| On Numerical Investigation of Nusselt Distribution Profile of Heat Sink Using Lateral Impingement of Air Jet | Dr. Siddique Umair | 2019-20 | CFD letters |

| Effect of process parameters on Defect Features and Mechanical Performance of Friction Stir Lap Welded AA6063 And ETP Copper joints | Dr. Ravi Terkar | 2019-20 | International Journal of Recent Technology and Engineering |

| Analyzing the effect of process parameters on Friction Stir Welded AA6063-ETP copper joint using Taguchi Technique | Dr. Ravi Terkar | 2019-20 | International Journal of Recent Technology and Engineering |

| Monte Carlo simulation based prediction model for ultimate tensile strength of Friction Stir Welded AA6063-ETP copper joint | Dr. Ravi Terkar | 2019-20 | IOP Materials science and Engineering |

| “Applications and challenges of arc welding methods in dissimilar metal joining” | Dr. Asha Ingle | 2019-20 | IOP Conference Series: Materials Science and Engineering |

| “Numerical analysis of microwave heating: Fundamentals and applications”, | Dr. Asha Ingle | 2019-20 | IOP Conference Series: Materials Science and Engineering |

| Improving the efficiency of the Lay-Up process in the manufacture of Solar Panels through time-study | Neepa Patel | 2019-20 | IOP Materials science and Engineering |

| A Review On Spd Processes To Produce Ultrafine-Grained And Multilayer Nanostructured Tubes | Mohan Bodkhe, Sanjeev Sharma | 2020-21 | INTERNATIONAL JOURNAL OF CREATIVE RESEARCH THOUGHTS – IJCRT (IJCRT.ORG |

| 4Qs Model To Assess The Student Learning Capabilities | Sunny Nanade | 2020-21 | International Journal of Advanced Science and Technology |

| Supplier Selection in MSME Gear Manufacturing Industries Using a MCDM Technique | Dr. Ashish Deshmukh, Dr. Hari Vasudevan | 2020-21 | Intelligent Manufacturing and Automation |

| A Study Of Computer Numerical Control (Cnc) Toolpath And Profile Milling On Cam Software | Zoya Rizvi | 2020-21 | INTERNATIONAL JOURNAL OF CREATIVE RESEARCH THOUGHTS – IJCRT |

| An Overview of Aluminium Matrix Composites: Particulate Reinforcements, Manufacturing, Modelling and Machining | Girish Joshi, Dr. Asha Ingle, Samadhan Deshmukh | 2020-21 | Materials Today: Proceedings, Elsevier Ltd. |

| An overview of the microstructure and mechanical properties of copper tube by SPD process | Mohan Bodkhe | 2020-21 | Materials Today: Proceedings, Elsevier Ltd. |

| A review on SPD processes used to produce ultrafine-grained and multilayer nanostructured tubes | Mohan Bodkhe | 2020-21 | Materials Today: Proceedings |

| Robust Prioritization of Remanufacturing Drivers for Original Equipment Manufacturer from End-user Perspective | Sawankumar Naik, Dr. Ravi Terkar | 2021-22 | Design Engineering |

| A Methodology to Develop and Statistically Validate a Framework of Design Factors to Drive Remanufacturing | Sawankumar Naik, Dr. Ravi Terkar | 2021-22 | Design Engineering |

| A Methodology to Develop and Statistically Validate a Framework of Design Factors to Drive Remanufacturing | Sawankumar Naik, Dr. Ravi Terkar | 2021-22 | Design Engineering |

| Role of Operations Management in Driving Growth of Manufacturing Industry in India | Girish Bagale and Sawankumar Naik | 2021-22 | Empirical Economics Letters |

| Factors affecting the deep drawing process–A review | Mohan Bodkhe | 2021-22 | Materials Today: Proceedings |

| Characterizing soil’s thermal property for earth air heat exchanger through experiment | Swati Donde | 2021-22 | Materials Today Proceedings |

| A Review on Tidal Energy Technologies | Chirag Shetty, Abhishek Priyam | 2021-22 | Materials Today Proceedings |

| Printing parameters and materials affecting mechanical properties of FDM-3D printed Parts: Perspective and prospects | M Doshi, A Mahale, SK Singh, S Deshmukh | 2021-22 | Materials Today: Proceedings |

| A comprehensive review on effect of printing parameters on mechanical properties of FDM printed parts | S Khan, K Joshi, S Deshmukh | 2021-22 | Materials Today: Proceedings |

| An overview on parametric study of photochemical machining process and its applications | J Vyas, L Sawant, S Tyagi, G Joshi, S Deshmukh, A Ingle | 2021-22 | Materials Today: Proceedings |

| Parametric review on friction stir welding for under water and dissimilar metal joining applications | S Naik, S Panda, S Padhye, G Lobo, G Joshi, S Deshmukh, A Ingle | 2021-22 | Materials Today: Proceedings |

| Review on mechanical characterization of 3D printed parts created using material jetting process | S Tyagi, A Yadav, S Deshmukh | 2021-22 | Materials Today: Proceedings |

Book Chapters

| Name of the author/s | Name of the Chapter | Name of the book | Name of Publisher | ISBN No. | Year |

| Trushna Prajapati and Abhishek Priyam | A Review on Photovoltaic Cells | Smart Energy and Advancement in Power Technologies | Springer | 978-9811949708 | 2022-23 |

| Dr. Ravi Terkar and Sushil Mishra | A Literature Review on Application of Lean Manufacturing Techniques | Recent Trends in Product Design and Intelligent Manufacturing Systems pp 877–893 | Springer, Singapur | 978-9811946059 | 2022-23 |

| Abira Mukherjee, Dr. Nagahanumaiah, Dr. Santanu Das | Exploration of Material Removal Mechanism in Micro-Nano-Electrical Discharge Machining | Recent Advances in Thermofluids and Manufacturing Engineering pp 459–469 | Springer | 978-9811943874 | 2022-23 |

All the classrooms are air-conditioned and equipped with Smartboard, PA System, and WiFi.

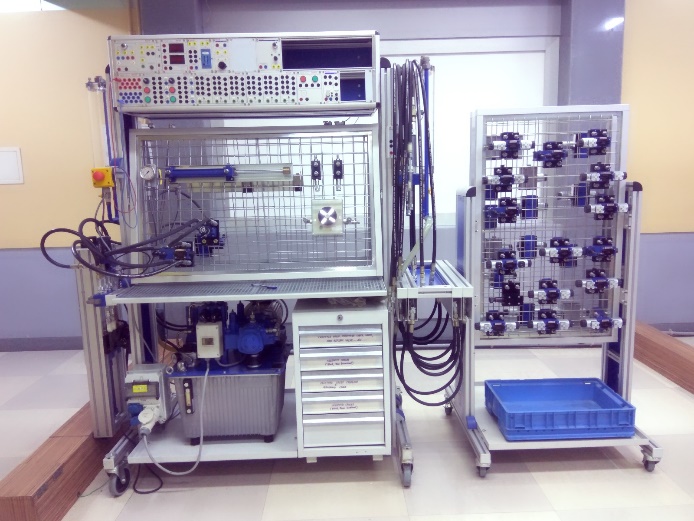

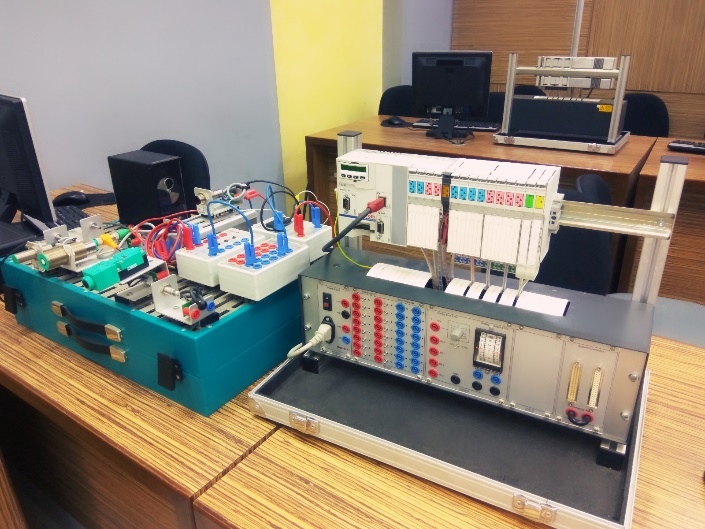

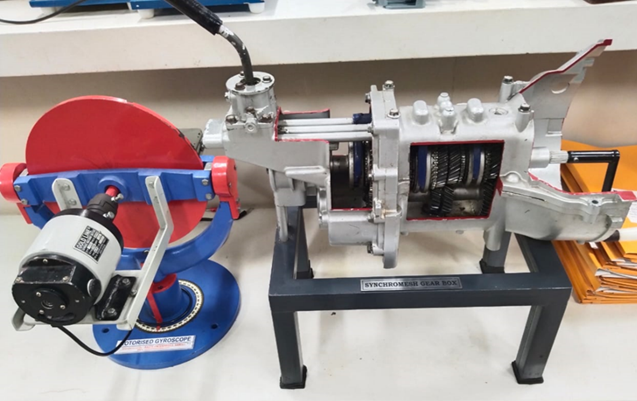

The NMIMS MPSTME Mumbai mechanical engineering laboratories are a hive of activity where theory and practice collide. Here, students conduct practical experiments to further solidify their grasp of mechanical concepts. All three of the mechanical engineering domains—manufacturing, design, and thermal—are served by laboratories. Modern labs include those for 3D printing, hydraulics, and pneumatics. Theory of Machines (TOM), Vibrations Laboratory, and CAD/CAM labs are two examples of design labs. Heat Transfer, IC Engine Laboratories, and Refrigeration & Air Conditioning are examples of thermal labs. The MPSTME mechanical engineering labs encourage creativity and the problem-solving abilities necessary for future engineers.

MACHINE SHOP

PLC & SENSORICS

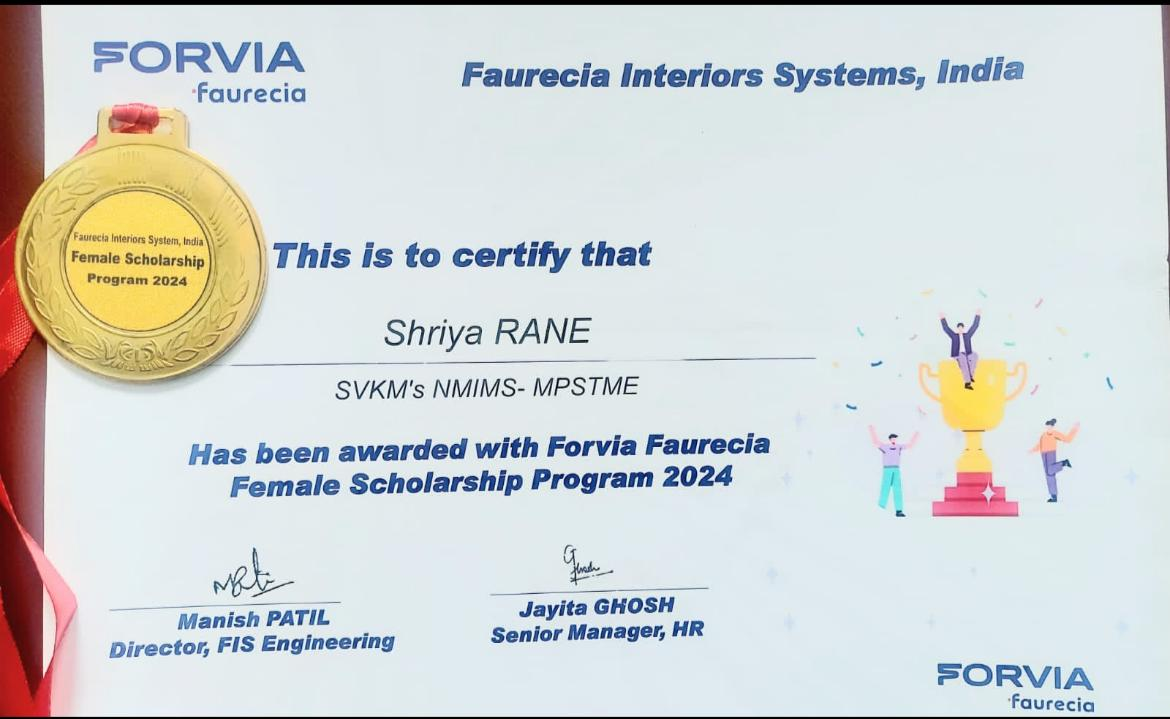

Shriya Rane, a fourth-year B Tech Mechanical Engineering student at the Mukesh Patel School of Technology Management & Engineering (MPSTME), has been awarded the highly acclaimed Faurecia Sustainable Mobility Solutions scholarship. Shriya secured a position in the top 10 out of almost 250 girls from various cities in Maharashtra who participated in the program. This achievement not only grants her a scholarship of INR 1,25,000 but also provides her with preference in Faurecia’s recruitment drive, besides opening doors to new opportunities, including mentorship, collaboration, and potential career prospects.

Associate Professor, HOD

Professor

Associate Professor

Assistant Professor

Assistant Professor

Assistant Professor

Assistant Professor

Associate Professor

Associate Professor

Assistant Professor

Assistant Professor

Assistant Professor

Assistant Professor

Assistant Professor

Assistant Professor

Assistant Professor

Assistant Professor

Assistant Professor

Assistant Professor

Assistant Professor

Assistant Professor

Assistant

Lab Asst.

Lab Asst.

Lab Asst.

Lab Asst.

Lab Asst.

Lab Asst.