Intake: 40

Program Duration: 4 years

Unique Features of the Program:

·AICTE approved

Program Constituencies:

The following are the program constituencies, which guide the inputs, delivery and outcomes of the program:

Faculty members are the owners of the program curriculum and are the guardians of the quality of knowledge dispensed. Their overall input and governance defines the educational objectives of the Mechanical Engineering program.

Employers come to the campus every year to interview students who are graduating. The Placement Cell has an active recruitment process for graduates. Most students seeking employment would have accepted positions by the time they graduate. The employers tend to view graduates as "industry-ready” and have an inherent interest in their quality as well as the quality of students progressing through the program.

The alumni are loyal members of the extended family of NMIMS. While they maintain a fond connection with the institution and its people, they also have the needed separation to evaluate the program objectively. NMIMS alumni connect by local chapters and alumni meet with the program coordinators and faculty members and provide advice about changes to be made to improve the program.

Program Educational Objectives (PEOs):

The Program Educational Objectives of the B.Tech.(Mechanical Engineering) Programme are to produce graduates who will

·Technical Growth - Graduates will be successful in modern engineering practice and entrepreneurship, integrate into the local and global workforce, and contribute to the economy of India.

·Professional Skills - Graduates will continue to acquire and demonstrate the professional skills necessary to be competent employees, assume leadership roles, and enjoy career success and satisfaction.

·Professional Attitude and Citizenship - Graduates will become productive citizens demonstrating high ethical and professional standards, make sound engineering or managerial decisions, and have enthusiasm for the profession and professional growth.

Student Outcomes (SOs):

Graduates of the B.Tech. in Mechanical Engineering program will have an ability to:

1. Identify, formulate, and solve complex engineering problems by applying principles of engineering, science, and mathematics.

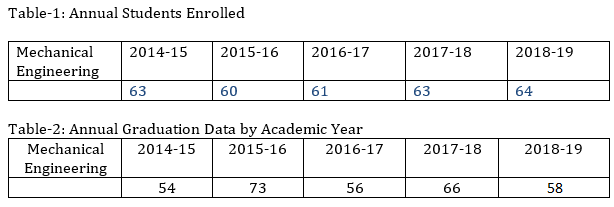

Annual Student Enrolment and Graduation data:

Curriculum:

New Curriculum (For Batches Enrolled in First Year from 2018-19)